Design

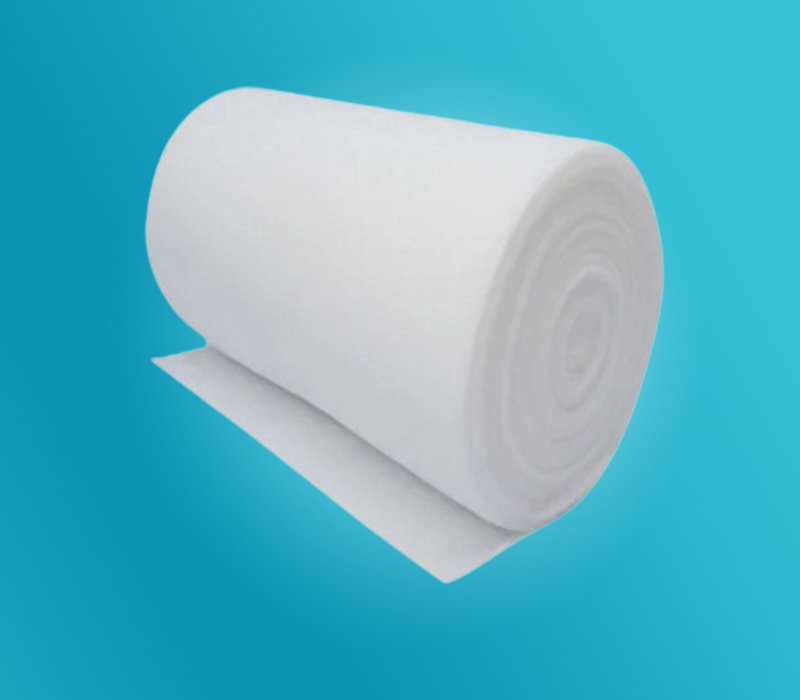

Industrial Filter Fabrics

Industrial Filter Fabrics are specially engineered woven and non-woven textiles designed for solid–liquid and dust filtration across various industries. Made from high-performance fibers such as polyester, polypropylene, nylon, aramid, and PTFE, these fabrics offer excellent filtration efficiency, durability, chemical resistance, and thermal stability. They are widely used in dust collector bags, filter presses, centrifuge liners, liquid filter bags, and air filtration systems. Available in different weights, weaves, and finishes, industrial filter fabrics ensure consistent performance, longer service life, and reliable separation results.

| Micron Ratings | 5 Micron |

| Material | Polypropylene |

| Cloth Size | 500 mm |

| Cloth Thickness | 0.5 mm |

| Weave Patterns | Double Layer Weave |

| Applications | Filter Press |

| Color | White |

| Country of Origin | Made in India |

FAQ

Find Out Answers Here

They are specialized fabrics made from synthetic or natural fibers, used for filtration applications in liquids, gases, and dust collection systems.

Industries such as cement, steel, chemicals, pharmaceuticals, food & beverages, mining, power plants, and wastewater treatment use them extensively.

Filter fabrics are available in polyester, polypropylene, nylon, aramid (Nomex), PTFE, cotton, and blends depending on the application

Woven fabrics offer strength, reusability, and precise particle retention.

Non-woven fabrics provide high permeability, better dirt-holding capacity, and cost-effectiveness.

Yes, depending on the material, filter fabrics can handle temperatures up to 280°C (aramid/PTFE) and resist strong acids, alkalis, and solvents.